Welcome to the website of HUBEI MIMO Trading Co., Ltd.!

Animal feed equipment

Product Details

Application range:

It is suitable for the production and processing of various aquatic feeds such as buoyancy, sinkability and slow settling, and it can also be applied to the production and processing of pet food.product features:

◆ High-life gear box; wear-resistant alloy screw bushing: screw service life> 22000 tons, bush service life> 50000 tons, free warranty for gear box 30,000 hours

◆ High-precision forging double-layer jacket of puffing cavity, enough strength to prevent jacket deformation or wear-resistant jacket loosening, can be heated or cooled;

◆ Equipped with overload protection clutch to ensure smooth, safe and reliable transmission. High-precision gears, imported high-quality bearings, oil seals, advanced gear box design and processing technology control technology;

◆ Equal gap, self-cleaning twin screw mechanism, effectively reduce the material residue in the barrel screw, easy to clean the barrel;

◆ Removable special material wear-resistant bushing, greatly reducing the cost of use;

◆ Effectively control the shearing force to ensure that all the materials mature in the expansion chamber and the particle expansion coefficient is consistent;

◆ The new fully wear-resistant alloy screw and the bimetallic expansion cavity inner sleeve effectively reduce wear and ensure long-term stable operation of the equipment under high-capacity and high-quality conditions;

◆ Effectively distribute reasonable shear forces in different areas of the extrusion cavity, and effectively increase output under the premise of ensuring high quality;

◆ The discharge of the turbulent discharge device makes the extruded extruded material more beautiful, and the output of the small hole diameter mold is increased by 30% -40%. The material shape is even and stable;

◆ The automatic control system simplifies the operation and reduces the labor intensity. All data are recorded, and the impact of the operator on the quality of the expanded product is minimized.

Technical Parameters:

| Model | Host power KW | Feeding power KW | Single shaft quenching and tempering power KW | Double shaft differential quenching and tempering power KW | Capacity T/H |

| XYPH120*2 | 220/250 | 2.2 | 5.5 | 18.5 | 5-7 |

| XYPH150*2 | 315/355 | 2.2 | 5.5 | 18.5 | 8-12 |

Applications:

| Feed varieties | Frog Feed Mill | Yellow Catfish Feed Milling | Freshwater Feed Milling | Crab Feed Milling | Crayfish Feed Milling |

| Host power KW | 200 | 200 | 200 | 200 | 200 |

| Host current A | 287 | 332 | 335 | 330 | 330 |

| Template aperture MM | Ф1.0 | Ф2.0 | Ф3.0 | Ф1.0 | Ф4.0 |

| Float rate | 100% | 100% | 100% | 100% | 100% |

| Density G / L | 425 | 4.1 | 383 | 620 | 621 |

| Expansion degree | 1.5 | 1.88 | 1.69 | 1.13 | 1.16 |

| Hourly output T / H | 3.2 | 5.2 | 5.8 | 3.4 | 5.1 |

Applications:

Ø0.5浮水料 |

Ø1.5浮水料 |

Ø1.5浮水料 |

Ø2.5浮水料 |

Ø4.0浮水料 |

Ø5.0浮水料 |

Accessories section:

Overload clutch protector |

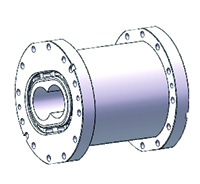

High-precision forging puffing cavity |

Efficient conditioner |

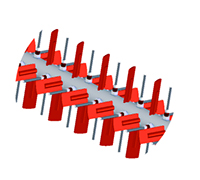

Kneading block (imported D2 steel) |

Previous:Raw material extruder

Next:Super micro pulverizer

Copyright © 2020 湖(hú)北美茂貿易有(yǒu)限公(gōng)司 版權所有(yǒu) 技(jì )術支持:蘇州網站建設 備案号:京ICP證000000号